Generative

Design – Programmed Identity

Ulf C. Cadenbach, Henrik Hornung, Tobias O. Schelkes

Prof. Hans Dehlinger

School

of Art, University of Kassel, Germany

e-mail:

ulfcadenbach@web.de, henrikhornung@web.de, tobischelkes@web.de

Abstract

The

following article sums up three different approaches, which have been developed

by the context of the department of product design at the School

of Art of Kassel. It is about 1. reflections of the “generative approach” in

design from a student’s point of view, 2. an experiment on the identity of a

fan-like object and 3. a concept for the generative creation of a lamp shade

made of laser cut sheet metal.

All three

texts deal with the methods, the results and the created identity of generative

design. The contribution of Henrik Hornung is rather reflecting, whereas the

one of Tobias O. Schelkes is experimental and the one of Ulf C. Cadenbach deals

directly with the design of a lamp shade.

All three

contributions cover fields (theory, experiment, design), which are significant

teaching methods of the department of product design.

1. Reflections about computer generated Design

1.1 Designing and Programming

The

processes of designing and programming are quite similar concerning their

structure. Both deal with solving problems. First of all, the existing problem

is to be analysed. If the circumstances are known, the requirements for the final

product need to be defined. Now the process of designing or problem solving

begins. This requires creativity, logical thinking, imagination and experience.

Connected with the question of the realization one of the design objects is now

implemented.

A programming

language has to be learned similar to that of a foreign language, including

vocabulary, orthography, syntax and grammar. But there is one important

difference: The programming language does not accept a colloquial language. It has to be used correctly in

order to be understood. In contrast to humans the computer is not fault-tolerant.

A programme

is not built via mouse click. The instructions must be written down explicitly.

But those proceedings do not have much in common with programming yet. Although

the programme runs step by step a huge number of instructions can be written directly

into one file and implemented from there in order to visualise the result.

At the

beginning of a programme there is an idea. It relies on a thorough analysis of

what seems to be possible. And it contains the thought that the result can be

reached through a process.

By

structuring work, e.g. organisation of procedures, the idea becomes a concept.

Gradually a programme is developed, which specifies generative rules for the

computational as well as the visual implementation within the rules of the used

programming language. This is actually programming. And it has much in common

with designing.

What we

colloquially call „programming“ is defined much more precisely by computer

scientists. For them the translation of a concept into algorithms is the most

important thing.

Computer

generated design can be understood as parametric design. Apart from many

boundary conditions a certain quantity of parameters remain open. By

manipulating them one can control the total behaviour of the final design.

1.2 Calculating and Designing

A huge

asset of the computer is the generation of quantity. And this is the

theoretical condition for the generation of variety. Within a given and a

conceptually described solution space it is observed in experiments that

computer programmes generate very surprising solutions.

What is the

reason for that? The computer is ignorant. It can inevitably only do what it is

dictated. Humans however are knowing. This knowledge affects their thinking and

acting permanently in the background. From their experience humans build

connections, draw parallels, associate incessantly without the possibility of

taking distance. They possibly end up with different solutions than the

computer. But those are mostly located outside the defined solution space.

The

computer works with high speed. Where humans give up on fatigued, the computer

calculates further. Where humans stop or change the process in another

direction because they estimate the probable success as little, the computer

calculates further. This weighs particularly if a random function is integrated

into a programme. Systematically (or randomly) solutions are generated. Many of

them are possibly useless, may it be for technical or aesthetical reasons. It

can however lead to interesting surprises.

Frequently some kind of “accident” occurs while designing. Every

designer might know these situations. Many of the big inventions of mankind

have been the result of an accident. If one tries to program a solution for a

design problem it is particularly interesting to recognise such cases. One even

tries to provoke them, to cause them consciously, which is a logical paradox.

How can one plan what occurs per definition only unplanned. Designing is

however in any way and always imprisoned in such and similar paradoxes. A tiny

programming error may cause either an error message or surprise with unexpected

results. Even if such results are not directly useful, they can be inspiration

for further considerations.

1.3 The Question about Identity

Döring [1]

describes „identity“ as unmistakableness („individuality“) over the time

(„continuity“) in different situations („consistency“). Unmistakableness in the

sense of a uniqueness is not only clearly recognisable with a computer

generated design (see fig. 1.1), but always as well obviously and directly

provable on the basis of numbers. Naturally solutions are generated that

resemble each other strongly. But apart from the fact that this is the same

with “handmade” design, exactly this is a further strength of the computer.

Even if a design is already, good an appropriate programme still generates

alternatives. The closer one gets towards its aim, the more one can restrict

the computer’s scope, the more parameter settings can be fixed and the more

precise and the more defined the design becomes.

Complex

programmes are constantly tested during their developing. The designer /

programmer constantly gets direct results during this process, which he must

evaluate. Process and result are therefore subjected to a constant quality

inspection. If necessary it can be intervened at any time. And that will always

be necessary, because even if many decisions are assigned to the programme,

even if design principles are defined as algorithms, it is the substantial task

of the designer to select the best one from the multitude of results. This

requires strength of judgement, sharp thinking and a good intuition.

2

Experiment on the Identity of a Fan-like Object

2.1 Explanation of the experiment

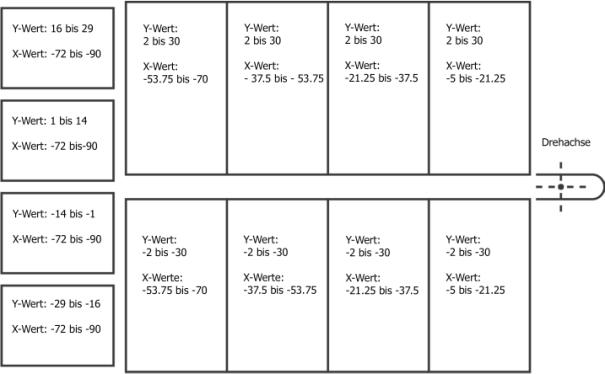

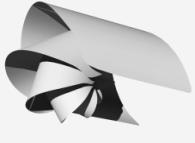

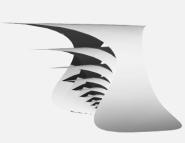

We describe

an experiment in which we follow the question how the identity of an object can

be generated, changed or exterminated by transforming a figure. We are

structurally defining a kind of “wing” (see Fig. 2.1) which is divided into

zones. These are restricted by a value facet. We are generating two kinds of

wings by inputting these information and some random variables into a script.

(1)

angular, polygonal (see Fig. 2.2)

(2)

roundish (see Fig 2.3)

Now we are

generating objects from these wings by rotating seven elements which are

uniform around a lightly varying rotation angle (29° to °33). Being

geometrically defined the axis is always the same. The similarity to a Chinese

fan of the objects generated in this way is wanted. The identity of such a fan

is highly been determined by the kind of elements and the way it is fan-like.

There are far more characteristic items of real Chinese fans like the kind of

folding, material properties and others.

Anyway we

can prove experimentally that the „generator“, which should generate fan-like

objects really generates fan-like objects.

Based on

this initial situation we ask the following questions:

(a) What is

the identity of the generated objects? Are they invariably of fan-like kind or

appeared any new identities?

(b) Are

there any possibilities to intensify the identity?

Do

we have any possibility to generate new identities with this generator which

differs from the fan-likes?

The

generator has been programmed as Rhino Script. The conclusions are shown in the

tables 1 and 2.

2.2 Discussing

the Achievements

There is a

distinct tendency to families of forms in both the polygonal and the round kind

of objects. I divide the families by an instant overview. There are to mention

four different groups or families in this experiment. The first group contains

plane fan-like objects like result 2 and 8 of the roundish kind and 5 and 16 of

the polygonal kind. The second family includes the lightly opened like result 6

and 7 of the roundish ones and 1 and 13 of the polygonal ones. The third group contains

the more leavened forms (roundish: 1 and 3 / polygonal: 2 and 3). The fourth

group are the ones which are opened in the upper area (roundish: 4 and 11 as

polygonal: 8 and 10) and so make up the other extreme.

It is

remarkable that the identity of the objects becomes more and more another with

more openings but never loses its relationship to the fan-like kind.

By

modifying the generator to more filigree results the fan-like identity becomes

more obvious. If the modifying results in forms that are more massive in the

base area and at the same time filigree in the upper area the identity

increasingly departs from the fan-like impression.

2.3 Conclusion of the Experiment

The more

waisted and / or symmetric the generated form is the more fan-like the objects

get. Regarding the results with the number 10, 15, 14 in table 2.1 and the

results with the number 2,11,18 in table 2.2 that becomes obvious. But at the

same time there is to mention that there are borders where the conclusion

obverts and so result is less a fan-like object. Therefore the objects with the

numbers 11, 19, 23 on table 2.1 and the results with the numbers 9, 10, 19 on

table 2.2. are an example which underline this.

The

conclusion of this experiment is that by rotating a defined number of elements

around a geometrically defined rotation axis the identity becomes more and more

a different one but nevertheless still is remarkably fan-like.

3. Generation of a Lampshade from Laser cut Sheet Metal

3.1 Task

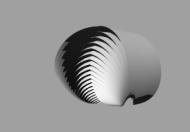

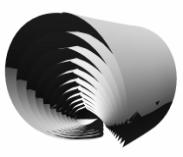

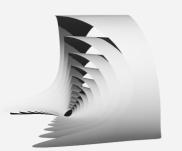

The basic idea was to design a lamp consisting of a number of sheet metal elements, which can be rotated around an axis. By using the same, but scaled shape for each element, similarities to the shell of a nautilus or pearlboat will appear.

We start with a sketched, closed curve, from which we extrude a surface. This surface is bent to a semicircular shape, copied, scaled, and rotated various times around a horizontal axis. By doing so we create a three-dimensional object.

The generative approach arised from trying to automatise iterating work processes. The shape was still sketched by hand but, to let the computer do the work of the iterating steps of copying, scaling and rotating, a small script was created for the CAD-Software Rhinoceros. Due to the fact that not every sketched shape could be processed with this one script (collisions appeared), parameters like number of elements, scale factor and rotation angle got varied and saved as stand-alone scripts. It was astonishing, which various appearances could be realised only by varying those three parameters (see fig. 3.2).

Next step was to define eight different versions of the script parameters, which represented the most characteristical appearances of the generated models (see fig. 3.1) With this “kind of generator” I tested the manually sketched shapes.

The characteristics of the models shown in fig. 3.1 could be summarised as:

- “less elements, little scale factor, large angle” versus “ many elements, large scale factor, little angle”

By using this procedure a large number of different appearances could be created, most of them were suitable for further processing. Some scripts were rejected, creating unrealisable models. For example the characteristic of “large number of elements, little scale factor (<0. 6), large rotation angle” lead to elements which were obviously too small for processing and even not visible in the model. But this helped to find out value sets for the later created generator, which almost exclusively create results suitable for processing.

In the next step a programme code was created (rhino-script), which as a generative system completely autonomous generates models of lampshades (see appendix 5.3)

This programme is fully functioning for relatively incomplex shapes. The shapes are generated by random, giving the designer or user the option to accept or decline the generated shapes for further processing (see fig. 3.4) The user also has the option to pick points by hand to create a shape and assign it to the generator for further processing (see fig. 3.3).

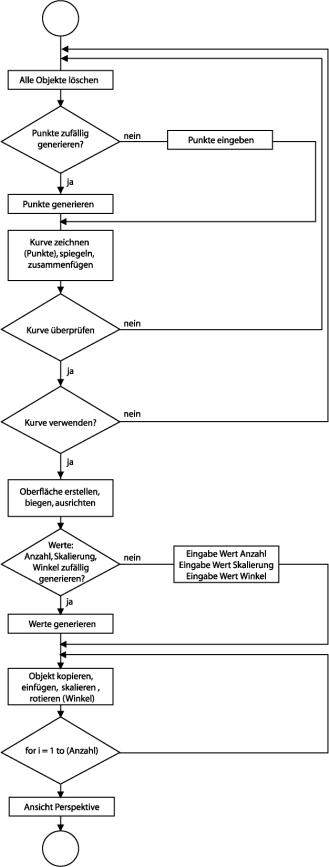

3.2 Operating Mode of the Generator

The generator creates eight coordinates by random. The value sets of this coordinates were chosen to avoid intersections of the generated curve. In a later version of the programme the value sets will change dynamically depending on the previous randomly created coordinates, to achieve a maximum variation of the curve.

The first and last coordinate points of the curve are located on the x-axis to get a closed shape by mirroring the curve. The following check routines make sure that the created shape is a closed curve, which is important for generating a surface and for processing the shape in a CNC lasercutter. If curve points are picked by hand, a check routine ensures that each curve point is assigned to a coordinate to avoid errors.

Now the curve is drawn, mirrored, joined and checked. A surface is now created from the emerging shape and bent semicircular.

That form is aligned parallel to the c-plane and the user is prompted to enter values for number of elements, scale factor and rotation angle. Optionally these values are generated semi-dynamically by random. From these values the CAD-Software builds the model and changes the view to perspective.

The next version will include some useful features, for example; loading of pregenerated shapes, saving of generated curves and models to files, an output of the processed values and coordinates and an option to export the shape as a .dxf-file for transferring the data directly to a CNC lasercutter (see fig. 3.6).

See fig. 3.7 for a flowchart, and appendix 5.3 for the complete program code

3.3 Conclusion

Generative design surely does not replace the classical design process. It is an interesting strategy for some concepts - like this one. In this concept a number of parameters can be varied without moving away from the basic idea.

A great advantage is to automatise iterating and tedious, but essential processes and get to significant results in a fraction of the time as compared to “handmade” models. In a given time-frame one can create and evaluate a much larger number of variations of a basic concept. Now it is possible to achieve results which in the classical design process would be declined due to lack of time.

Since the generator is deaf, dumb and blind, it will deliver concepts which the designer would never have processed nor considered due to his own preoccupation. Further on, completely new concepts arise from so called “accidents” or imprecisenesses defining parameters. These new concepts may vary from the basic idea but could be interesting by all means and lead to a completely different result.

Last but not least, it is important for students to deal with the concept of “mass customisation”, which surely show some similarities to generative / parametrical design processes.

The generative / parametrical design approach is considered a useful add-on to the classical design approaches. One should not be afraid to make use of this strategy if it seems to be useful. Consequently it is absolutely inevitable for designers to deal with this form of design approach.

4 References

[1] Döring, N.: „Sozialpsychologie des Internet. Die

Bedeutung des Internet für Kommunikationsprozesse, Identitäten, soziale

Beziehungen und Gruppen“, Hogrefe, Göttingen 1999, P. 255

Abb. 1.1: 156_curves_16_grey computergenerierte

Zeichnung, Henrik Hornung 2004

Fig. 1.1: 156_curves_16_grey computer generated

drawing, Henrik Hornung 2004

Abb. 1.2: 155_curve_16_grey, computergenerierte

Zeichnung, Henrik Hornung 2004

Fig.

1.2: 155_curves_16_grey computer generated drawing, Henrik Hornung 2004

|

|

Abb.

2.1: Strukturelle Beschreibung eines Elements

Fig. 2.1: structural

description of an element

Abb.

2.2: Beispiel Outline rundlich Abb.

2.3: Beispiel Outline eckig

Fig.

2.2: example outline roundish Fig.

2.3: example outline polygonal

|

|

|

|

|

|

|

|

1 |

|

2 |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

5 |

|

6 |

|

|

|

|

|

|

|

|

|

7 |

|

8 |

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

11 |

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

14 |

|

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

17 |

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

19 |

|

20 |

|

21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

|

23 |

|

24 |

|

Tab.

2.1: Ergebnisse 7 – 24

Tab. 2.1: results 7– 24

|

|

|

|

|

|

|

|

1 |

|

2 |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

5 |

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

8 |

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

11 |

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

14 |

|

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

17 |

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

19 |

|

20 |

|

21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

|

23 |

|

24 |

|

Tab. 2.2: Ergebniss 1 – 24

Tab. 2.2:

results 1 – 24

|

Beispiel 1

30/15/90 |

Beispiel 2 12/15/80 |

||

|

Beispiel 3 5/15/80 |

Beispiel 4 20/15/60 |

||

|

Beispiel 5 20/45/60 |

Beispiel 6 20/45/85 |

||

|

Beispiel 7 4/80/85 |

Beispiel 8 4/60/60 |

||

|

|

|

|

|

|

|

|

|

|

Abb. 3.2: “von

Hand” erzeugte 3D-Modelle

Fig. 3.2: “hand-crafted” 3D-models

|

|

|

|

|

|

|

|

|

|

|

|

Abb. 3.3:

Lampshade Generator V3.3, parametergesteuert

Fig. 3.3: Lampshade Generator V3.3, using

parameters

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Abb. 3.4:

Lampshade Generator V3.3, zufallsgesteuert

Fig. 3.4: Lampshade Generator V3.3, randomly generated

|

|

|

|

Abb. 3.5: Von

Hand erzeugte Modelle, 0.3 mm Aluminium

Fig. 3.5: handcrafted

models, 0.3 mm Aluminium

|

|

|

Abb. 3.6: Prototyp Edelstahl, 0,5mm CNC lasergeschnitten

Fig. 3.6: prototype stainless steel, 0,5mm CNC

lasercut

Abb. 3.7: Flussdiagramm Lampshade Generator

Fig. 3.7: flowchart Lampshade Generator